Unsere Branchen

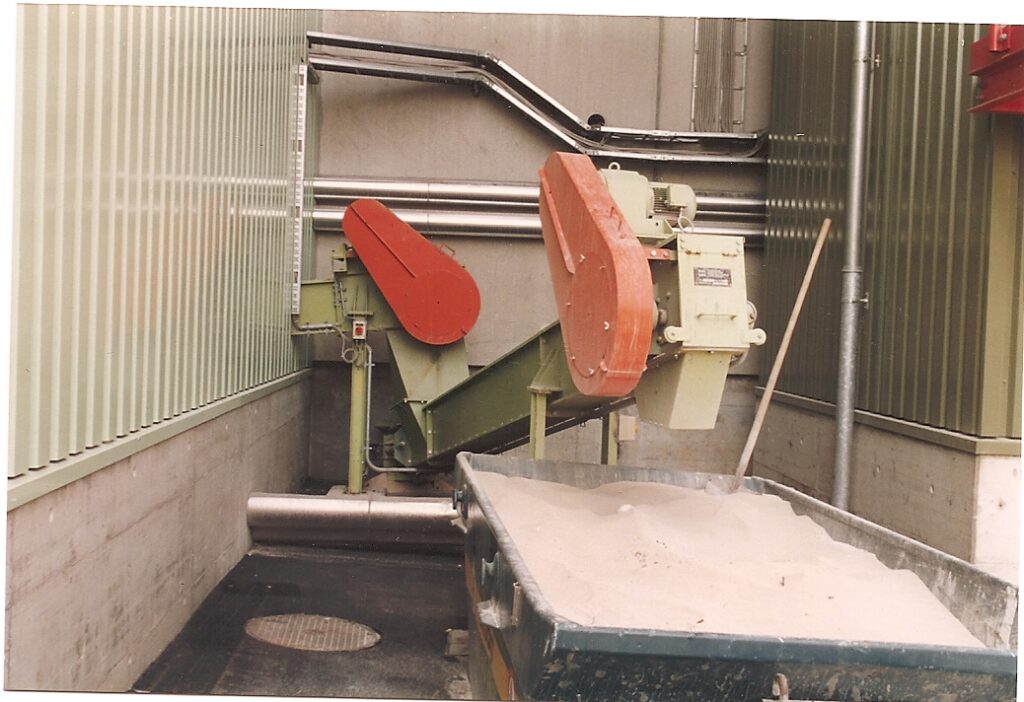

Holzindustrie

In der holzverarbeitenden Industrie kommen zur Förderung von Spänen und Hackschnitzel unsere Trogkettenförderer, Gurtförderer, Elevatoren und Förderschnecken zum Einsatz.

Weiterlesen...

Beim Trogkettenförderer wird eine Einstrang- oder Zweistrangkette mit eng aufeinanderfolgenden Mitnehmern in einem geschlossenen Trog mit mäßiger Geschwindigkeit vorwärtsbewegt. An der Aufgabestelle fällt das Fördergut auf das fördernde Kettentrum und wird zunächst durch die Querstege und dann durch die bereits in Bewegung befindliche Gutschicht mitgenommen. Die Bewegung der unteren Gutschichten wird bis zu einer bestimmten, sich selbst einstellenden Höhe auf die oberen übertragen, so dass das gesamte Fördergut zusammen mit der Kette einen mit gleichmäßiger Geschwindigkeit dahingleitgenden Körper bildet. Der Querschnitt des geförderten Materials ist dabei um ein Vielfaches größer als die Mitnehmereinrichtung. Mit relativ kleinem Querschnitt können also große Mengen befördert werden. Trogkettenförderer können von einer Steigung von 0 – 90 Grad eingesetzt werden.

Bestandteile eines Trogkettenförderers sind: Antriebs- und Endstation, Trog, Förderkette.

KEITEL CONVEYORS setzt nur Förderketten aus gesenkgeschmiedeten Gliedern ein, wobei unser Maßstab Bühler-Qualität ist.

Durch die robuste Konstruktion eignen sich mechanische Trogkettenförderer hervorragend zum Dauereinsatz. Wartungs- und Instandhaltungsaufwand sind in diesen Systemen relativ gering. Weiter von Vorteil ist die trockene und staubfreie Förderung durch das geschlossene System.

Eine weitere Möglichkeit zum Fördern von Schüttgütern ist der Einsatz von Gurtförderern, die etwas günstigere Alternative zum Trogkettenförderer. Gurtfördersysteme können bis zu einer Steigung von ca 27 Grad eingesetzt werden. In der Regel handelt es sich bei Gurtförderern um offene Systeme, so dass das Fördergut nicht vor Nässe geschützt ist, auch ist die Fördermenge im Vergleich zum Trogkettenförderer geringer.

Soll Schüttgut nur über kurze Strecken transportiert werden, eignen sich Förderschnecken. Hier ist das fördernde Element eine Schraubenfläche aus Blech oder Bandstahl, die um ihre Achse gedreht wird und das Fördergut in einem Trog oder Rohr vorwärts schiebt.

Kläranlagen

In Kläranlagen liefern wir Trogkettenförderer, Förderschnecken und Förderbänder. Unsere Trogkettenförderer befinden sich unterhalb der Kammerfilterpressen zum Abtransport von entwässertem Klärschlamm.

Weiterlesen...

Um eine lange Standzeit der Förderer zu gewährleisten, werden die Tröge im Fördertrum mit Basalt ausgemauert.

Kraftwerke

Trogkettenförderer werden unterhalb der Elektrofilter eingesetzt, da sie druckdicht ausgeführt werden können. Auch für den Transport heißer Asche eignen sich Trogkettenförderer und Förderschnecken ausgezeichnet.

Weiterlesen...

Um den Verschleiß so gering wie möglich zu halten, können auch hier im Bedarfsfall die Trogkettenförderer mit Basalt ausgemauert werden.

Recycling Material

Immer häufiger wird Rohspan aus Recyclingmaterial hergestellt. Hier setzen wir unsere jahrzehntelange Erfahrung mit den unterschiedlichsten Schüttgütern wie Schlamm, Holz, Recycling und Fasern ein.

Weiterlesen...

Da Recyclingmaterial ein sehr ungenau definiertes Fördergut ist, werden in den letzten Jahren unsere Trogkettenförderer, sowie Förderschnecken weitestgehend aus HARDOX hergestellt. Das ist zwar in der Verarbeitung, Biegen und Kanten, etwas aufwendiger, erhöht die Standzeit unserer Anlagen jedoch um mehr als 70 Prozent.

Weitere Branchen

Umweltindustrie

z.B. Kläranlagen, Biomasse, Entwässerung, Müllverwertung

Papierindustrie

z.B. Hackschnitzel, Pulp

Energieindustrie

z.B. Kraftwerke, Brennstoffzulieferung

Chemische Industrie

z.B. Granulate

Lebensmittelindustrie

z.B. Salz, Zucker

Mühlenindustrie

z.B. Soja, Weizen